Introducing an Innovative Brake Disc for Commercial Vehicles

Thursday 21st, Jul. 2016We have been exporting to mainland Europe,

Africa and Australia since 1990.

Our products include brake discs/rotors,

brake pads, brake drums, brake shoes, brake

chambers and slack adjusters for commercial

and off-road vehicles.

What really sets us apart is our state-of-the-art

in-house R&D facility. If you need a precision

engineered, premium quality alternative part,

then we will work closely with you to develop a

bespoke, exclusive product from idea through

specification, production and delivery.

This results in a range of high quality, lower

cost products designed and supplied exclusively

for you.

The discs, drums, pads and shoes are made to

premium brand formula and comply with the

new ECE90 regulation. Our brake chambers

are also high quality and comply with industry

standards SAEJ1469.

We have been the sub-contractor for

First Bus UK for all their bus disc requirements

since 2009. In addition we have also supplied

discs & drums to all the major commercial

vehicle brands for many years.

The Problem

Nearly 85% of road accidents are

caused by brake failures.

Brake discs work to slow or stop a vehicle by

providing a friction force against the rolling

motions of the wheels. At the same time

however, the discs are subjected to major

compressive and tangential loads along with

severe frictional heating.

As a result, most failures of brake discs happen

in the form of radial cracks or fractures.

Vehicles mostly effected by thermal cracking

are commercial vehicles including fire engines,

motorway coaches, mountain buses and

truck racing.

In commercial vehicles, the flash temperature

on the braking surface can be increased

to higher than 900°C in a few seconds by

the clamping force of the brake caliper,

consequently the repeated loads and heating

causes surface radial cracks and plastic

deformation.

The Solution

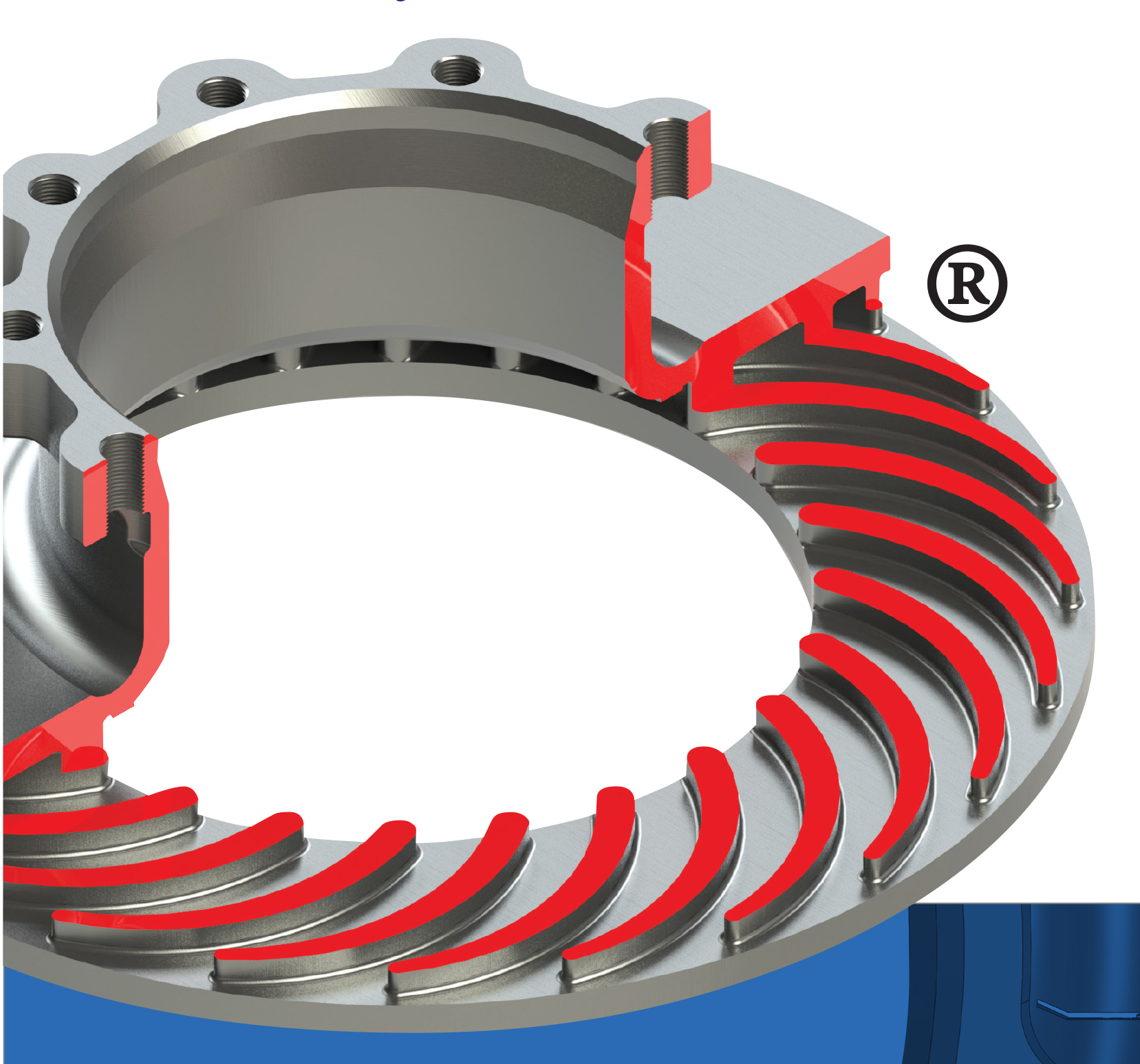

In order to reduce the temperature and thermal stresses,

our approach is to introduce the advanced concept of

Racing Car Turbine Vent Design into the re-design of

commercial vehicles.

The advantages brought about through

the new design include the following:

• Significantly increased air flow

• Lower working temperature

• Elimination of radial thermal cracks

• Reduced pad and disc wear

• Decrease in Caliper maintenance

• Disc weight reduced by up to 10%

Call us today or email and see how we can help with the management of your fleet's brakes.